FTR&F

Core Expertise

Napkin to Product

And everything in between

Specification Capture

Perhaps the most important part of the entire design. If you get this wrong, you open the door to a bad, expensive product, planning and requirement slip, team tensions,...

There is no way to spend too much time on this part of the process. We will work with you and your team and ask all the right questions, to bring all the right answers to the table. To make sure we all understand where we are going.

System architecture

KISS. Keep it simple, stupid. Do not add features nobody needs. Do not underestimate the effort to add "free" features. Don't try to make a product that covers every customer and every market. Make up your mind, and stick to it.

If you do all that, we will propose an architecture that is simple and elegant. Powerful and efficient. And we will tear out every single part you don't need.

Sometimes.

Because the first question to ask is "how many do you need". If you need 100 000, all of the above makes sense. If you need only one, it makes much more sense to take off-the-shelf components and solutions, no matter how much overkill it is, no matter if it's ugly or pretty, no matter what the cost.

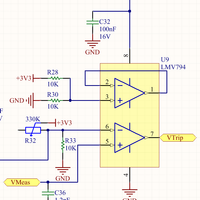

Schematic capture

This is where your system choices are translated into details and components. We use a database of components that are easy to source, cheap and up to the task. Those will be complemented by whatever specific components that are required.

This is where we connect the dots: analog, power, RF, microcontrollers, FPGAs, memory... If there are concerns of of rising complexity or cost, we will feedback to the system architecture or even specification capture if needed.

At the end of this stage, it is quite possible to provide the customer with a tentative quoted BOM.

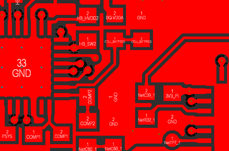

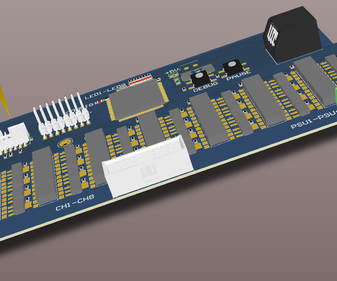

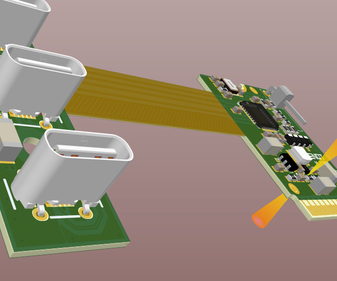

Layout

The "what" and "how" has been determined before this, but whether it will actually work is determined here. Routing an analog control line under a noisy transformer will ruin your day every time.

That is why we make sure the engineer that generated the schematics does the layout. He knows what is critical and where he can cut some corners. He knows what volumes are to be expected, how and where it is to be produced and he will take all of that into account.

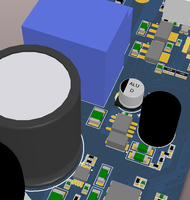

Our PCBs are designed for easy manufacturing and are accurately modelled in 3D so the mechanical team can evaluated compatibility and jumpstart their development. You can run the boards through your regular channels or you can ask us to initiate and follow up production.

Board debug & startup

Probably the most tricky and least predictable part of the development process. The only way to decrease the debugging load is to increase the expertise in all the stages before this. It is entirely impossible to make any promises but our goal is clear: "First Time Right". If we are unable to reach this goal, it is possible some of the previous steps will get an encore.

We have our own equipment so in case you have no electronic engineering department of your own, this decreases your investment considerably.

Oh, and if you need more gear for your own lab you should probably check our T&M page!

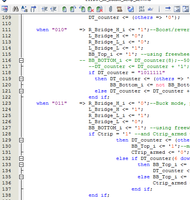

FPGA coding

We have the required expertise to do some simple work (glue logic, interfaces, ...) but you should look elsewhere for more complex coding. The more complex the VHDL requirements are, the more you'll be paying for the education of one of our people and the more the overall efficiency will decrease.

Production preparation

By keeping the complexity down during requirement and schematic capture phases, choosing industry standard components, drafting from an elaborate database and by keeping production in mind at all times, the groundwork for easy and efficient production has been laid. However, you still have to choose where to produce your units, whether to source your components yourself, whether to do some manual assembly inhouse... Regardless of your choices, regardless of the quantities you need, we can help you finding the right partners and know the right people to make it happen.

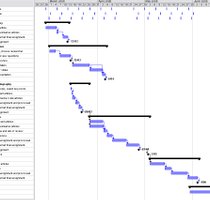

Project management

If you choose us for one of your projects, this automatically includes project management. Depending on the size and complexity of the project, this may be an informal affair or a full scale project management, including weekly status reports, cost tracking, planning updates and projections, resource management...

If you choose us as a resource for only a segment of the project (to layout your board, to write the VHDL code...), we can either integrate seamlessly in your team or take the lead if you do not have a suitable project leader available.

Nice to know!

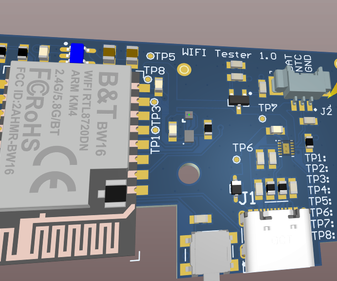

We use Altium Designer!

We have years of experience with Altium Designer. We believe it offers a great ballance between price and features.

We have our own licence so you dont have to worry about seat count or having to buy a licence for your project.

FPGA Expertise!

We designed with all major vendors, ranging from puny MAX CPLDs, over Spartans right to Smartfusion devices.

Our core expertise includes both the physical implementation (schematics and board layout) and basic VHDL programming.

We'll be happy to advise you what to choose and with our wide experience we will be able to find our way to a succesful implementation quickly, flawlessly and efficiently!

Design For Manufacturing & Cost!

Having had the actual SMD equipment machine both on a factory floor 10 000km away and in the room next to our desk we are in an excellent position to make sure your product can be made quickly and efficiently, with minimal intervention from your side if you wish.

Understanding how and where to produce is only a part of the cost control process. Understanding that by the time components are to be sourced, 80% of the cost saving opportunities have been lost is of primary importance.

At FTR&F, finding the optimum cost spot is an integral part of the design cycle, with equal parts of common sense, general design rules, understanding the industry, all blended together in a balancing act that is as close to art as it is to science!